Laser-based surface functionalisation

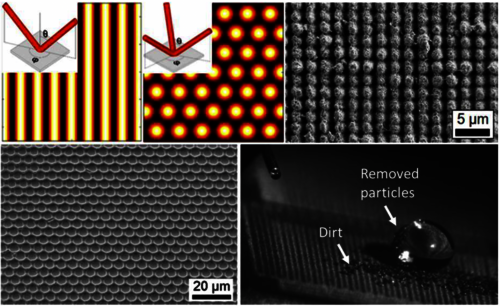

State-of-the-art: Various methods are commonly used for surface texturing, including traditional mechanical processes (milling, grinding, honing), chemical or electrochemical processes (photo-lithography, electron assisted etching), and non-traditional processes which need an external source of energy (jet texturing, focused electron beam, laser ablation). A common disadvantage of these methods is typically the low productivity due to the size and complexity of features required for surface functionalisation. In particular, photon-based fabrication methods offer several advantages due to their remote and thus contactless operation, flexibility, and precise energy deposition. However, recent improvements in the average power and repetition rates of pulsed laser systems have increased the demands for laser beam scanning and/or beam shaping over the current upper limit of beam deflection. These issues can be solved, for instance, using optical approaches and devices (such Spatial Light Modulators) to split the laser beam into several sub-beams and therefore dividing the total laser average power several times. A very well-known phenomenon that can be observed on almost any material after the irradiation when using ultrashort laser pulses are Laser-induced periodic surface structures (LIPSS) which can also be used for producing functional surfaces. Another innovative solution for high-speed surface patterning is Direct Laser Interference Patterning (DLIP). At laboratory scale, interference patterns can be obtained by splitting a coherent laser beam into two or more sub-beams which are later overlapped on a workpiece (Fig. 1.2). The periodic intensity distribution is transferred to the material's surface, allowing the direct surface patterning of many materials. The used laser wavelength limits the resolution achieved with this method up to Λ ~ λ/2 (spatial period). Therefore, structures up to the sub-micrometre scale are possible using this technology. These advanced surface topographies have shown to be able to provide surface with antibacterial properties, self-cleaning and icing properties as well as low friction coefficients, however mainly only in 2D surfaces.

Funding