Motivation

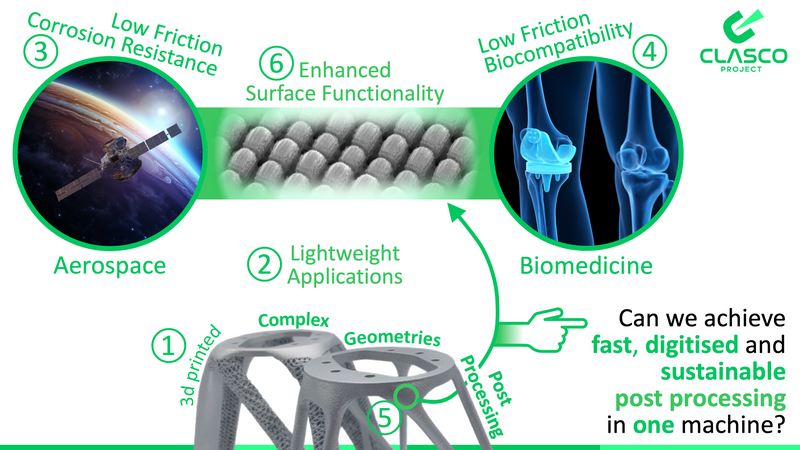

The CLASCO project is at the forefront of innovation in additive manufacturing (3D printing), focusing on parts with complex geometry ①. These parts are essential for lightweight applications ②, particularly in the aerospace (including aircraft and satellites) and biomedicine (such as implants) sector. Post processing is considered a key element to improve specific properties to make 3d printed parts possible for these high-tech applications ③,④.

Taking Measures:

- Weight Reduction with complex geometry parts to reduce materials use.

- Property Enhancement for targeted applications: friction, corrosion resistance, and biocompatibility improvement.

Adressing current (global) Challenges:

- Rough part surfaces after additive manufacturing production process ⑤: This roughness prevents a targeted surface finish.

- Sustainability: We incorporate sustainable practices to achieve and optimise our environmental friendliness (material and energy use).

- Digitisation: Using digital technologies such as artificial intelligence to improve the precision and efficiency of our manufacturing and finishing techniques.

The CLASCO Solution:

Increase the functionality of part surfaces by tailoring the surface topography ⑥ in one efficient machine: The CLASCO project explores a two step laser process in one machine for achieving fast, digitized, and sustainable post-processing on parts with complex geometries for aerospace and biomedical applications.

Introduction Video

Funding