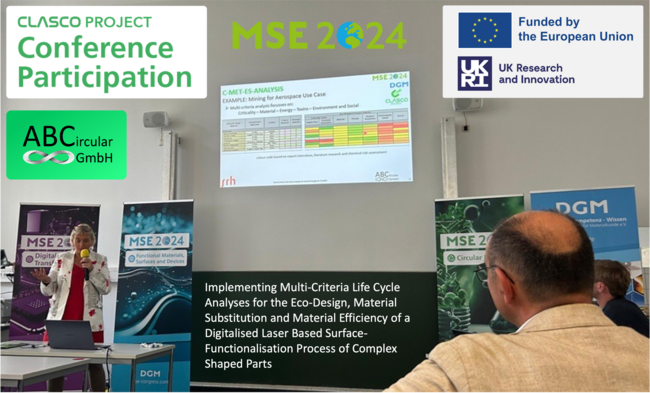

Prof. Beck’s presentation, titled “Implementing Multi-Criteria Life Cycle Analyses for the Eco-Design, Material Substitution and Material Efficiency of a Digitalised Laser-Based Surface-Functionalisation Process of Complex Shaped Parts,” brought to light innovative approaches to sustainability, especially in complex manufacturing processes.

The study applies a holistic life cycle approach to evaluate and improve product performance at every stage, from material extraction to end-of-life. Each product's lifecycle was mapped using process trees to track material flows, followed by a comprehensive Material Energy Toxins (MET) analysis extended to include Criticality, Environmental and Social Impacts - collectively known as the C-MET-ES framework. Through this structured assessment, the study identifies critical life cycle "hotspots" and provides actionable insights for eco-design improvements.

A key outcome of CLASCO's research is an eco-design checklist developed for CLASCO's use case owners to guide them toward sustainability-sensitive design choices. The study also identified specific risks associated with post-processing, particularly in the use of chemicals, through a detailed chemical hazard risk assessment. This meticulous process not only highlights environmental benefits, but also provides the basis for quantitative life cycle assessments, allowing comparisons between traditional and CLASCO-developed methodologies.

The CLASCO project is a model for integrating sustainability into digitized manufacturing, paving the way for greener, more efficient production processes.

Learn more about this inspiring project and its impact on sustainable manufacturing on our homepage.