The program opened with presentations from each project, introducing their technological approaches and application fields. Sure2Coat presented corrosion-resistant coatings for aluminum housings and aeroengine components, designed to extend service life and improve reliability. FABulous demonstrated high-resolution 3D metasurfaces that increase the precision of optical sensors while reducing their size. BILASURF showcased bio-inspired laser riblets that reduce drag in hydro turbines, contributing to higher energy efficiency. SYNTECS focused on real-time monitoring systems for laser surface texturing, which ensure process stability and support sustainable manufacturing.

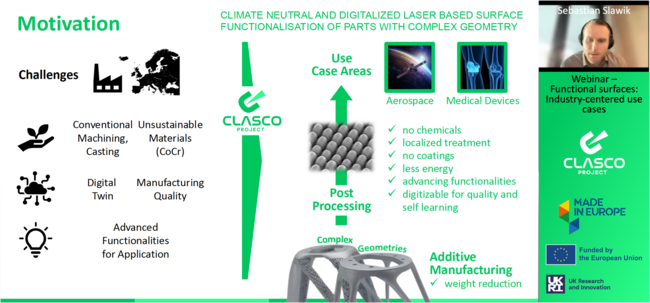

CLASCO’s contribution centered on additive manufacturing, with a focus on laser polishing and surface functionalisation as post-processing techniques. Sebastian Slawik from the German Society for Materials Science (DGM) presented the project’s motivation, core technological elements, and use cases. CLASCO’s laser-based methods improve the biocompatibility of biomedical implants and enhance durability and corrosion resistance in aerospace components. These innovations demonstrate how advanced surface treatments can significantly increase component performance and reliability in demanding industrial applications.

The presentations were followed by a panel discussion on technical and economic challenges in implementing laser-based functional surfaces, including opportunities for cross-sector collaboration. A live Q&A session concluded the event, enabling direct exchange between participants and experts.

This webinar demonstrated how European collaboration strengthens innovation capacity in manufacturing and underlined the role of laser technologies in building a more sustainable and competitive industry.

Watch the recording: www.youtube.com/watch